What Is Polyaspartic?

Polyaspartic coatings are next-generation aliphatic polyurea systems engineered for rapid cure times, UV stability, and superior abrasion resistance. Compared to epoxy, polyaspartic delivers high-build protection with faster return-to-service—ideal for industrial floors, garages, and commercial facilities.

Our formulations balance viscosity, pot life, and reactivity, giving installers longer working time without sacrificing cure speed.

Discover the Brij Advantage →

Where Polyaspartic Excels

Industrial floors • Warehouses • Garages • Retail • Food & beverage • Labs • Decorative metallic systems

-

2–4 hr — Typical light traffic -

High — UV/Gloss Retention -

Excellent — Chemical Resistance -

Low — Odor Options

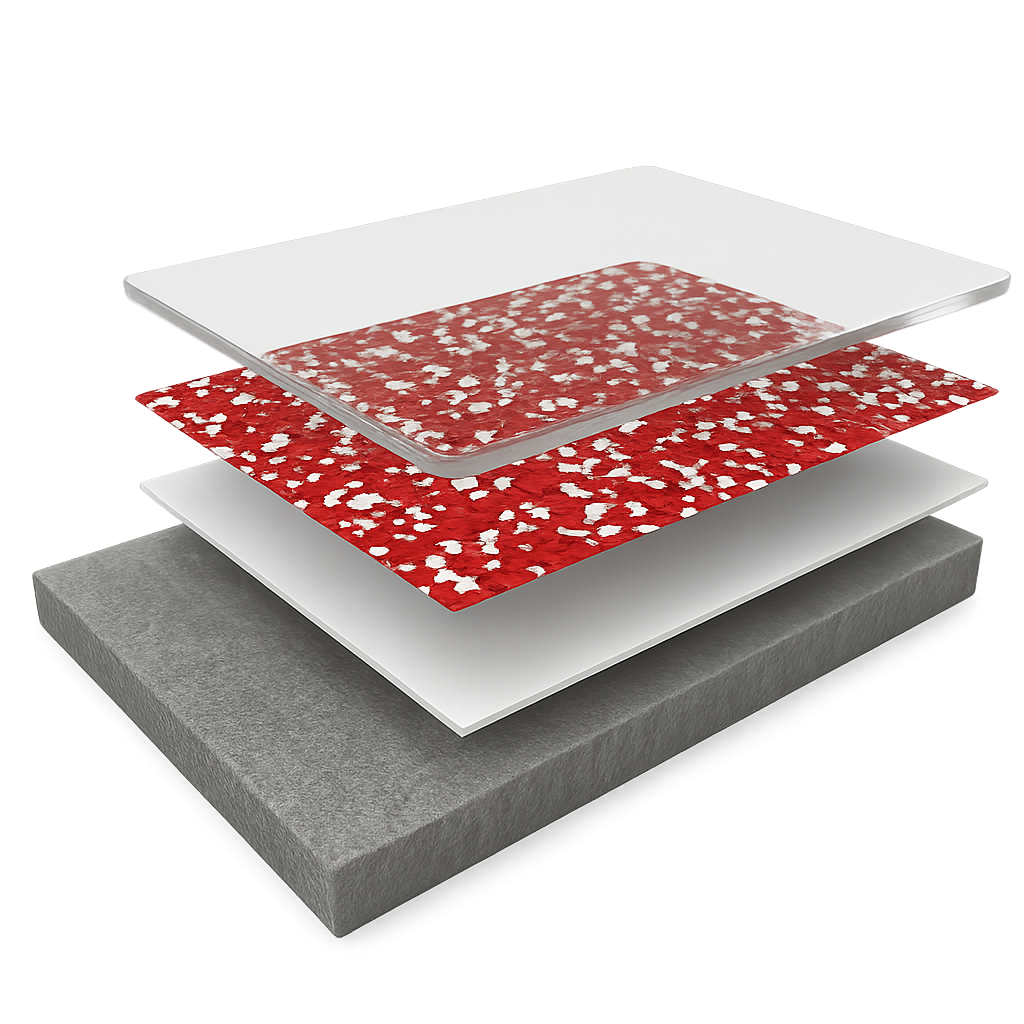

The Science Behind Polyaspartic Technology

Polyaspartics are synthesized through a Michael Addition reaction between diamines and maleic acid diesters, resulting in secondary aliphatic diamines. The molecular structure incorporates steric hindrance through the diamine component, providing a key advantage over conventional polyamines. Unlike typical polyamines—which react too rapidly with low-cost aromatic polyisocyanates—polyaspartics exhibit controlled reactivity. This makes them a unique class of hindered secondary amines, whose reactivity can be precisely tailored to achieve specific performance characteristics while maintaining compatibility with standard application techniques.

Why Choose BRIJ Polyaspartic

-

Fast return-to-service — hours, not days -

UV-stable, non-yellowing finish -

Chemical & impact resistance for harsh use -

Lower installed cost via crosslinking efficiency -

Ideal for industrial, commercial, and decorative floors